Category: KCGO News

The latest news from Kalamia Cane Growers and Kalagro for Members Only.

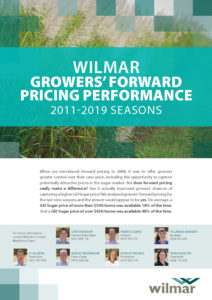

Wilmar – Understanding Foward Pricing

Wilmar Newsletter (Foward Pricing Performance) – 8th April 2020

Media Release – Queensland Covid 19 – Tuesday April 7

Wilmar Growers’ Foward Pricing Performance 2011 – 2019 Seasons

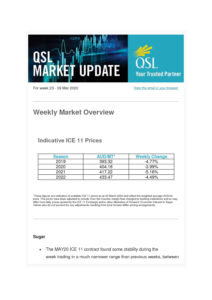

QSL Weekly Update – 4th April 2020

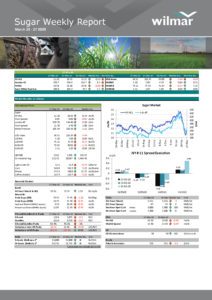

Wilmar Market Update – 3rd April 2020

CHEMICAL SAFETY TRAINING COURSE UPDATE

Due to the current situation with COVID19 the following Chemical Safety Training Course has been delayed. Any growers interested in participating in this course in the future are asked to please contact 1800626681 to lodge their expression of interest.

RE: CHEMICAL SAFETY TRAINING COURSE (FORMERLY CHEMICAL ACCREDITATION)

TRAINER SERVICES PTY LTD, RTO No 40867

on behalf of and in partnership with

COUNTRYCO TRAINING PTY LTD (Geoff Paton)

• Pre-course training questions MUST be completed by Initial participants PRIOR to the course.

• Initial (1 day) & Update (1/2 day) courses are conducted concurrently.

• Venue & Times to be confirmed after close of bookings – 6th Apr

• Course locations are flexible and determined by bookings

Competency Units: AHCCHM307 Prepare and apply chemicals to control pest, weeds and diseases

AHCCHM304 Transport and store chemicals

Successful Initial & Update Training participants will be issued with a Statement of Attainment and Accreditation Card

Accreditation is valid for 5 years.

Training provided by Geoff Paton, from Countryco Training Pty Ltd

Required for most QA Programs including Freshcare, Graincare, FeedSafe, Feedlot Accreditation, & Reef Protection Regulations in the Wet Tropics, Burdekin & Mackay/Whitsunday catchment areas.

BEST COURSE GUARANTEED: at the end of the day if you are not happy with the course speak to the trainer and you will receive a full refund.

CLIENT FEEDBACK: Clear, simple & helpful language used throughout. Excellent explanation of all aspects of chemical use, handling & storage. Very practical & useful help & teaching that I will be able to build upon immediately. Being able to ask lots of questions & then get good answers was very helpful. Mark W.

QSL Market Update – 1st April 2020

2020 SEASON & COVID-19

2020 SEASON & COVID-19

There have been a number of communications issued from Wilmar and QSL over recent weeks providing updates of practices and processes that have been put in place in order to minimise the impact of COVID-19. Updates, which included “ QSL frequently asked questions” have been uploaded to our web page for members information.

KCGO posed a number of questions to both QSL and Wilmar that were relevant to the storage and export of raw sugar from the Burdekin region through STL’s Townsville facility. Q & A response received from QSL is detailed below, some of which has also been addressed in their recent communications to growers. Wilmar are yet to provide a formal response to questions posed with their current efforts, as a first step, in having State/Federal Government to officially recognise the Sugar Industry as an “essential service” .

KCGO is also aware peak industry bodies in conjunction with Dept of Agriculture and Fisheries have formed working groups to investigate various scenarios and possible impacts to the sugar industry during these uncertain times. QSL, ASMC, STL and CANEGROWERS are known to be participating. Matters being addressed include but not limited to:

• Workforce availability

• WHS

• Business Continuity

• Supply Chain and Logistics

Questions that QSL have responded to are:

• Will there be any residual 2019 sugar remaining in QSL’s Townsville STL terminal storage facilities as of commencement of 2020 season?

At this stage, QSL expect that there will be something like two cargoes left in stock (60,000 tonnes) depending when the season starts. This is quite normal.

• What is the storage capacity of STL Townsville facilities?

The terminal at Townsville can hold 770,000 tonnes of which allocation to QSL/Wilmar is roughly 50/50. Have confirmed with STL storage capacity of its four sheds is approx. 750,000 tonnes (Shed 1- 130kt, Shed 2- 150kt, Sheds3/4- 470kt). This combined holding capacity represents 66% of the Burdekin crop.